Momwe mungakulitsire njira zoponyera zama spheroidization

The spheroidization mlingo wa zoweta wamba spheroidal graphite kuponyera chitsulo castings chofunika kufika msinkhu 4 kapena pamwamba, (ndiye, mlingo spheroidization ndi 70%), mlingo spheroidization akwaniritsa ndi foundry ambiri ndi za 85%. M'zaka zaposachedwa, ndikupanga chitsulo chopangidwa ndi nodular, makamaka m'mafakitale omwe ali ndi zofunikira kwambiri pakupanga mphamvu zamagetsi ndi mtundu woponyera, gawo la spheroidization limafunikira kufikira mulingo 2, ndiye kuti kuchuluka kwa spheroidization kumafikira zoposa 90%. Kampani ya wolemba idasanthula ndikuwongolera momwe spheroidization ndi inoculation imagwiritsidwira ntchito QT400-15, komanso spheroidizing agent ndi inoculant, kotero kuti kuchuluka kwa spheroidization kwa nodular cast iron kudafika 90%.

1. Njira yoyambirira yopangira

Ndondomeko Choyambirira kupanga:

- Chida chosungunulira chimatengera uvuni wamkati wapakati wa 2.0T ndi 1.5T mafakitale owotchera mafakitale;

- Kapangidwe ka QT400-15 madzi achitsulo chosakanizika ndi ω (C) = 3.75% ~ 3.95%, ω (Si) = 1.4% ~ 1.7%, ω (Mn) .0.40%, ω (P) ≤0.07%, ω ( S)) ≤0.035%;

- Spheroidizing wothandizila ntchito spheroidizing mankhwala ndi 1.3% kuti 1.5% RE3Mg8SiFe aloyi;

- Inoculant yogwiritsidwa ntchito pochizira mankhwala ndi 0.7% ~ 0.9% 75SiFe-C alloy. Chithandizo cha spheroidizing chimagwiritsa ntchito njira ziwiri zogwedeza ndi kuzizira:

Choyamba, 55% ~ 60% ya chitsulo imapangidwa, kenako spheroidizing imachitika, kenako inoculant imawonjezeredwa, kenako madzi ena onse achitsulo amawonjezeredwa.

Chifukwa cha njira zachizolowezi zothira spheroidization ndi inoculation, kuchuluka kwa spheroidization komwe kumazindikirika ndimayeso amodzi ophatikizika a 25 mm nthawi zambiri amakhala pafupifupi 80%, ndiye kuti gawo la spheroidization ndi lachitatu.

2. Ndondomeko yoyesera yosinthira kuchuluka kwa spheroidization

Kuti muwonjeze kuchuluka kwa spheroidization, njira yoyambira kupopera ndi kukokomeza yasinthidwa. Njira zazikuluzikulu ndi izi: kukulitsa kuchuluka kwa spheroidizing wothandizila ndi inoculant, kuyeretsa chitsulo chosungunuka, ndi chithandizo cha desulfurizing. Kukula kwa spheroidization kumayesedwanso ndimayeso amodzi a 25 mm. Dongosolo lenileni ndi ili:

- (1) Unikani chifukwa cha kuchepa kwa spheroidization koyambirira. Amaganiziridwa kuti kuchuluka kwa spheroidizing wothandizila kunali kocheperako, kotero kuchuluka kwa spheroidizing wothandizirako kunakulitsidwa kuchokera ku 1.3% mpaka 1.4% mpaka 1.7%, koma kuchuluka kwa spheroidizing sikunakwaniritse zofunikira. . (2) Lingaliro lina ndikuti kuchuluka kwa spheroidization kocheperako kumatha kubwera chifukwa cha kuchepa kwaubambo kapena kuchepa kwa chonde. Chifukwa chake, kuyesaku kudakulitsa kuchuluka kwa inoculation kuchokera ku 0.7% mpaka 0.9% mpaka 1.1%, ndipo kuchuluka kwa spheroidization sikunakwaniritse zofunikira.

- (3) Pitirizani kusanthula ndikukhulupirira kuti pali zophatikizika zambiri pazitsulo zosungunuka komanso zinthu zina zosokoneza spheroidization zomwe zingayambitse kutsika kwa spheroidization. Chifukwa chake kuyeretsa kwakukulu kwazitsulo zachitsulo kumachitika. Kutentha koyeretsa kutentha kwambiri kumayang'aniridwa pa 1500 ± 10 ° C, koma kuchuluka kwake kwa spheroidization sikunapitirire 90%.

- (4) Kuchuluka kwa ω (S) kumadya kwambiri kuchuluka kwa spheroidizing ndikufulumizitsa kuchepa kwa spheroidization. Chifukwa chake, chithandizo cha desulfurization chikuwonjezeka kuti chichepetse madzi amtundu wachitsulo ω (S) kuchokera ku 0.035% mpaka ochepera 0.020%, koma kuchuluka kwa spheroidization kumangofikira 86% yokha. Zotsatira zoyeserera pazinthu zinayi zomwe zatchulidwazi zikuwonetsedwa mu Gome 1. Kapangidwe kake ndi mawonekedwe amakina oyeserera a mphako sanakwaniritse zofunikira.

3. Ndondomeko yomaliza yomaliza yasinthidwa

3.1 Njira zakukonzanso

- Zida ndizopangidwa ndi chitsulo cha nkhumba, zopanda zingwe zopanda dzimbiri kapena zochepa zotenthetsera;

- Kuwonongeka kwa chitsulo chosungunuka ndi kuwonjezera phulusa la soda (Na2CO3) ku ng'anjo;

- Gwiritsani ntchito wothandizila wa Foseco 390 kuti musadye poizoni m'thumba;

- Chithandizo champhamvu ndi Fozco Nodulizer;

- Kugwiritsa ntchito silicon carbide ndi ferrosilicon kuphatikiza inoculation.

Chitsulo choyambirira chachitsulo chosungunulira njira yatsopanoyi: ω (C) = (3.70% ~ 3.90%, ω (Si) = 0.80% ~ 1.20% [akuponya ω (Si final) = 2.60% ~ 3.00%], ω ( Mn) ≤ 0.30%, ω (P) ≤0.05%, ω (S) .0.02%. Chitsulo chosungunuka choyambirira ω (S) chimaposa 0.02%, phulusa la soda limagwiritsidwa ntchito pophulika kutsogolo kwa ng'anjo, chifukwa desulfurization reaction is a endothermic reaction, Kutentha kwa desulfurization kumafunika kuyang'aniridwa mozungulira 1500 ° C, ndipo kuchuluka kwa soda phulusa lowonjezedwa kumayang'aniridwa pa 1.5% ~ 2.5% kutengera kuchuluka kwa ω (S) pakasungunuka m'ng'anjo .

Nthawi yomweyo, phukusi la spheroidizing limagwiritsa ntchito phukusi lodziwika bwino la madamu. Choyamba, onjezerani 1.7% ya Foseco NODALLOY7RE wothandiziranso kupopera mankhwala mbali ya damu pansi pa phukusi, phatikirani ndi kugwiranagwirana, ndipo gwiritsani ntchito 0.2% ya ufa wa silicon carbide ndi 0.3% yaying'ono. , ndipo atapondaponda, imakutidwa ndi chitsulo, ndipo 75% Foseke 0.3 inoculant imawonjezeredwa mbali ina ya ladle yachitsulo chosungunuka. Mukadina chitsulo, 390% ~ 55% ya voliyumu yonse yazitsulo idasungunuka koyamba. Kukwanitsa kuchita izi kumalizidwa, 60% 1.2SiFe-C inoculant imawonjezedwa ndipo chitsulo chosungunuka chimatsuka, ndipo slag imatsanulidwa.

Zotsatira za mayeso a 3.2

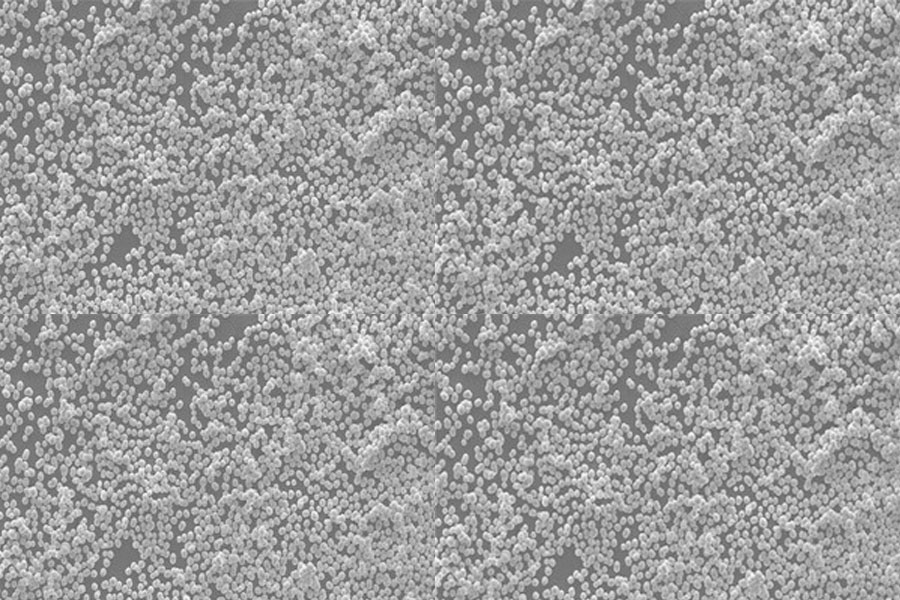

Kapangidwe ka chitsulo choyambirira chosungunuka isanachitike komanso itatha desulfurization, makina ndi mawonekedwe a metallographic a 25mm single test wedge-shaped block block, ndi njira yowunika ya spheroidization mu kapangidwe ka metallographic imadziwika ndi dongosolo la kusanthula kwazithunzi za metallographic .

4. Kuwunika zotsatira

4.1 Kutengera kwa zinthu zazikulu pamlingo wa spheroidization

- C, Si: C imatha kulimbikitsa graphitization ndikuchepetsa chizolowezi choyera pakamwa, koma kuchuluka kwa ω (C) kumapangitsa CE kukwera kwambiri komanso kupangitsa graphite kuyandama, yomwe imawongoleredwa ndi 3.7% ~ 3.9%. Si akhoza kulimbikitsa luso la graphitization ndikuchotsa cementite. Si ikawonjezedwa ngati mankhwala osakaniza, imatha kuchepetsa mphamvu zopangira chitsulo chosungunuka.Pofuna kusintha mphamvu ya inoculation, kuchuluka kwa ω (Si) mu chitsulo choyambirira chosungunuka kunachepetsedwa kuchoka ku 1.3% mpaka 1.5% mpaka 0.8% mpaka 1.2%, ndipo kuchuluka kwa ω (komaliza Si) kumayendetsedwa pa 2.60% mpaka 3.00%.

- Mn: Panthawi ya crystallization, Mn amachulukitsa chizolowezi chachitsulo chopitilira muyeso ndikupititsa patsogolo mapangidwe a carbides (FeMn) 3C. Pakusintha kwa eutectoid, Mn amachepetsa kutentha kwa eutectoid, imakhazikika komanso kuyenga pearlite. Mn alibe mphamvu zambiri pakukula kwa spheroidization. Chifukwa cha mphamvu ya zopangira, nthawi zambiri amayang'anira ω (Mn) <0.30%.

- P: Pamene ω (P) <0.05%, imasungunuka mwamphamvu mu Fe, ndipo ndizovuta kupanga phosphorous eutectic, yomwe imakhudza kwambiri kuchuluka kwa spheroidization ya ductile iron.

- S: S ndichinthu chodetsa nkhawa. S imagwiritsa ntchito Mg ndi RE mu spheroidizing wothandizila panthawi ya spheroidizing reaction, kuletsa graphitization ndikuchepetsa kuchuluka kwa spheroidizing. Sulfide slag idzabwereranso ku sulfure chitsulo chosungunuka chisanakhazikike, ndikuwononganso zinthu zopatsa mphamvu, kupititsa patsogolo kuchepa kwa spheroidization, ndikupanganso kuchuluka kwa spheroidizing. Kuti tikwaniritse kuchuluka kwa spheroidization, kuchuluka kwa ω (S) pazitsulo zosaphika kuyenera kuchepetsedwa kufika pochepera 0.02%.

Chithandizo cha Desulfurization

Mlanduwo utasungunuka, tengani zitsanzo ndikuwunika momwe zimapangidwira. Kuchuluka kwa ω (S) ndikokwera kuposa 0.02%, kuwonongeka kumafunika.

Mfundo ya koloko phulusa desulfurization ndi: ikani phulusa la koloko mu ladle, gwiritsani ntchito chitsulo chosungunuka kuti musunthe ndikusunthira, phulusa la soda limawonongeka pakatentha kwambiri, momwe zimapangidwira ndi Na2CO3 = Na2O + CO2 ↑: Na2O yopangidwa ndi mu chitsulo chosungunuka kachiwiri Kukwaniritsidwa ndikupanga Na2S, (Na2O) + [FeS] = (Na2S) + (FeO).

Na2CO3 imalekanitsa ndi kuthetsa CO2, kuyambitsa chisokonezo chachitsulo chosungunuka, chomwe chimalimbikitsa kuwonongeka kwa zinthu. Koloko phulusa slag n'zosavuta otaya ndi tiwolokere msanga, ndi desulfurization anachita nthawi ndi waufupi. Pambuyo pakuwonongeka, slag iyenera kuchotsedwa munthawi yake, apo ayi ibwerera ku sulfure. Chithandizo cha Pre-deoxidation, spheroidization and inoculation Foseke 4.3 wothandiziratu wothandizila amatenga chithandizo cha pre-deoxidation mchikwama, ndipo nthawi yomweyo kumawonjezera graphite nucleation pachimake ndi kuchuluka kwa magawo a graphite m'dera lililonse, ndipo amathanso onjezerani kuchuluka kwa mayikidwe a Mg. Sinthani kwambiri kuthekera kokana kutsika kwachuma ndikuwonjezera kuchuluka kwa spheroidization. Inchulant ya Fochke ili ndi ω (Si) = 390% ~ 60%, ω (Ca) = 70% ~ 0.4%, ω (Ba) = 2.0% ~ 7%, pomwe Ba amatha kuwonjezera nthawi yolimbikira. Kalasi ya NODALLOY11RE ya Fozco Nodulizer yasankhidwa, ndipo ω (Si) = 7% ~ 40%, ω (Mg) = 50% ~ 7.0%, ω (RE) = 8.0% ~ 0.3%, ω (Ca) = 1.0 % ~ 1.5%, ω (Al) <2.5%. Popeza chitsulo chosungunuka chimakhala ndi desulfurization ndi pre-deoxidation chithandizo, zinthu zomwe zimawononga nodulizers mu chitsulo chosungunuka zimachepetsedwa kwambiri, motero nodulizer wokhala ndi low zochepa (RE) amasankhidwa kuti achepetse kuwonongeka kwa spheroidal graphite morphology ndi RE ; Chofunikira kwambiri ndi Mg; Ca ndi Al atha kutengapo gawo polimbikitsa makulitsidwe. Pogwiritsa ntchito silicon carbide ndi ferrosilicon kuphatikiza inoculation mankhwala, malo osungunuka a silicon carbide ndi pafupifupi 1.0 ° C, ndipo graphite crystal nucleus imakulitsidwa nthawi yolimba, ndipo milingo yayikulu ya ferrosilicon imagwiritsidwa ntchito popangira inoculation, yomwe ingalepheretse spheroidization kuchepa.

5 Mapeto

Popanga chitsulo chotulutsa ferritic nodular, pamene kuchuluka kwa spheroidization kumafunikira kufikira 90%, izi zitha kutengedwa:

- (1) Sankhani zolipiritsa zapamwamba kuti muchepetse zinthu za de-spheroidization pamlanduwo.

- (2) Sankhani othandizira kupanga spheroidizing ochepa ω (RE) kuti muchepetse kuwonongeka kwa RE pa morphology ya spheroidal graphite.

- (3) Zomwe zili ndi ω (S) zachitsulo choyambirira chazitsulo ziyenera kukhala zosakwana 0.020%, zomwe zimachepetsa kugwiritsidwa ntchito kwa ma nodulizers, makamaka zinthu zomwe zimapukusidwa zomwe zimadyedwa ndi sulfurization yachiwiri ya sulfide slag.

- (4) Pre-deoxidize chitsulo chosungunuka, kuonjezera chiwerengero cha magawo a graphite m'dera lililonse, kuwonjezera kuchuluka kwa spheroidization, kumathandizira kwambiri kuthana ndi kuchepa kwachuma, ndikuwonjezera nthawi yolimbikira.

- (5) Kuchepetsa kuchuluka kwa ω (Si) mu chitsulo choyambirira chosungunuka, kuwonjezera kuchuluka kwa spheroidizing wothandizila, inoculant ndi othandizira ena am'mbuyomu, ndikulimbikitsa chithandizo cha inoculation.

Chonde sungani komwe adachokera ndi adilesi iyi kuti musindikizenso: Momwe mungakulitsire njira zoponyera zama spheroidization

Minghe Kampani Yoponyera ali odzipereka kupanga ndi kupereka zabwino ndi magwiridwe antchito a Kutayira Mbali (zitsulo zoponyera magawo osiyanasiyana zimaphatikizapo Woonda-Wall Die kuponyera,Kutentha Kwambiri Kuponyera,Cold Chamber Die Casting), Round Service (Ntchito Yoponyera Akafa,Cnc Machining,Kupanga Zinthu, Pamwamba pa Chithandizo) .Mtundu uliwonse wa Aluminium die kuponyera, magnesium kapena Zamak / zinc kufa kuponyera ndi zofunikira zina ndizolandilidwa kuti mutilankhule.

Motsogozedwa ndi ISO9001 ndi TS 16949, Njira zonse zimachitika kudzera pamakina opanga makina otsogola, makina a 5-axis, ndi malo ena, kuyambira ma blasters mpaka makina ochapira a Son Son.Minghe alibe zida zapamwamba komanso ali ndi akatswiri gulu la akatswiri odziwa ntchito ndi oyang'anira kuti mapangidwe kasitomala akwaniritsidwe.

Wopanga mgwirizano wopanga kufa. Mphamvu zimaphatikizapo magawo ozizira a aluminium die akuponya kuchokera ku 0.15 lbs. mpaka 6 lbs., kusintha mwachangu kukhazikitsidwa, ndi makina. Ntchito zowonjezera zimaphatikizapo kupukuta, kunjenjemera, kudodometsa, kuwombera mfuti, kupenta, zokutira, zokutira, msonkhano, ndi zida. Zipangizo zomwe zimagwiritsidwa ntchito ndizophatikiza ma alloys monga 360, 380, 383, ndi 413.

Zinc kufa kuponyera kapangidwe ka ntchito / ntchito zofananira zamakono. Makonda opanga mwatsatanetsatane wa zinc kufa. Kuponyera kwakung'ono, kuponyedwa mwamphamvu, kuponyedwa kosiyanasiyana, zopangidwa ndi nkhungu, mayendedwe amtundu ndi odziyimira payokha komanso zotsekera zotsekedwa zimatha kupangidwa. Zokongoletsa zimatha kupangidwa kutalika ndi mulifupi mpaka 24 mkati. Mu +/- 0.0005 in. Kulolerana.

ISO 9001: 2015 wopanga wa magnesium wamtundu wakufa, Mphamvu zake zimaphatikizapo kuponyera kwa magnesium kufa mpaka 200 ton chipinda chotentha & 3000 chipinda chozizira, kupanga zida, kupukuta, kuumba, kusinthanitsa, ufa & kupaka kwamadzi, QA yathunthu ndi kuthekera kwa CMM , msonkhano, kulongedza & kutumiza.

ITAF16949 yotsimikizika. Ntchito Yowonjezera Yowonjezera Phatikizani kuponyedwa kwa ndalama,kuponya mchenga,Kukongoletsa, Anataya zathovu kuponyera,Kuponyera kwamakedzana,Kuponyera Kutulutsa,Permanent Mold KuponyeraZolimba zimaphatikizaponso EDI, thandizo la uinjiniya, kutengera kolimba komanso kukonza kwina.

Akuponya Makampani Zolemba Pazigawo za: Magalimoto, Mabasiketi, Ndege, Zida zoyimbira, Watercraft, Zipangizo zamagetsi, Sensor, Models, Zipangizo zamagetsi, Zitseko, Mawotchi, Makina, Ma Injini, Mipando, Zodzikongoletsera, Ma Jigs, Telecom, Kuunikira, Zipangizo Zachipatala, Zithunzi za zithunzi, Ma Robot, Ziboliboli, Zomvera, Zida Zamasewera, Zida, Zoseweretsa ndi zina zambiri.

Kodi tingakuthandizeni kuchita chiyani?

∇ Pitani patsamba lofikira Akuponya China

→Zida zoponyera-Peza zomwe tachita.

→ Malingaliro Owonjezeka Pafupi Ntchito Zamachitidwe Akufa

By Wopanga Minghe Die Casting | Magulu: Nkhani Zothandiza |Zofunika Tags: Zotayidwa kuponyera, Kutaya Zinc, Kuponyera Magnesium, Kutumiza Titanium, Kuponya Chitsulo chosapanga dzimbiri, Kutayira Mkuwa,Kuponyera Mkuwa,Akuponya Video,Mbiri ya Kampani,Zotayidwa Die kuponyera | Ndemanga Off